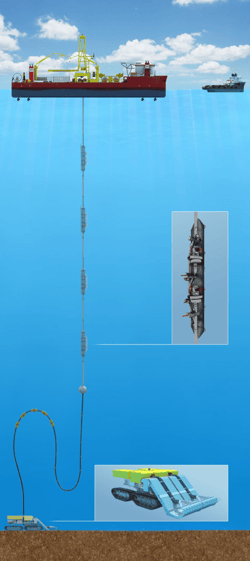

How do you keep power, data, and control steady—five and a half kilometers below the surface?

That was the challenge behind Blue Nodules, an EU project exploring how to harvest polymetallic nodules without harming the deep-sea environment.

For a cutting-edge EU Research Project, DeRegt was asked to join an EU-funded consortium of 14 companies. Industry, research institutes and service companies across seven different countries joined forces.

From system goals to cable reality

When you’re building ROV systems for extreme depths, you think in system requirements: power, control, uptime, cost. At DeRegt, we turn those system needs into cable behavior—cables that bend, lift, and perform exactly as your mission demands.

For Blue Nodules, that meant designing a 5.5 km umbilical connecting a crawler, six booster pumps, and a surface vessel. Each segment had to deliver power and communication flawlessly under crushing pressure.

The result? A double-armoured steel design, with automated clamping for launch and recovery. One common design for every section—easy to swap, easy to repair, and built to last.

Why it matters

In deep-sea operations, downtime isn’t inconvenient—it’s mission-critical.

In deep-sea operations, downtime isn’t inconvenient—it’s mission-critical.

So we design for reliability first: redundancy where it counts, smart geometry to manage load, and protection for every fragile fibre.

Because when your ROV system goes that deep, your cable becomes your lifeline.

What we've learned

One of our main challenges for the sake of economic viability and sustainability was ensuring that we had a one-fits-all solution. The same design for each of the sections of the vertical transport system was selected. So that if a part needs to be replaced or you need to cut back, you can simply replace a single part and shift the other components.

Learn more about the challenges and the needed collaboration in this video:

Automatic clamping system

For safety reasons, no human interference was allowed, so we needed to develop a clamping system that allows the cables to be fixed to the vertical transport system. Therefore we’ve developed a system that automatically clamps and de-clamps the umbilicals along the 5.5 km long hose during the launch and recovery of the system. An innovative method was used to minimize the mechanical loading onto the umbilicals and vertical transport system.

Robustness

The umbilicals contain a double steel armor to transfer loads and to protect the electrical and optical components from crushing. Fragile components are placed towards the center of the cable. For corrosion prevention, we’ve jacketed every single steel wire. This means that if the cable is damaged and its water tightness is compromised, it will have a minimal impact on its durability.

The Ultimate ROV Cable Guide

Each ROV Cable Design is different, and every subsea project requires its specific specifications. In our Ultimate ROV Cable Guide, you can read everything there is to know about projects like these, ROV cable construction, and trends in the ROV market.

For any questions about ROV Cables, schedule a meeting with me here or download the Guide below for free: