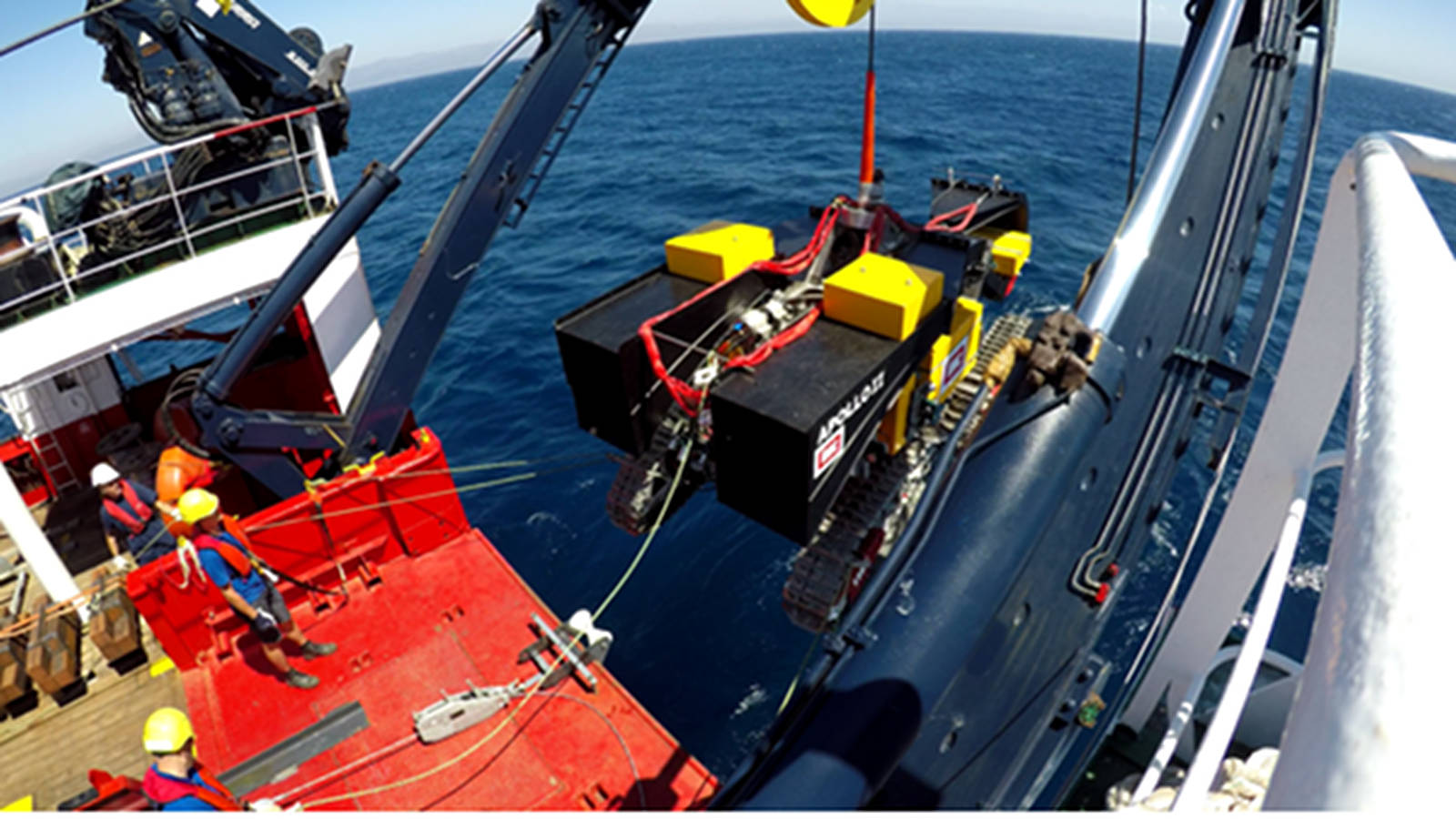

The construction of an ROV umbilical cable is specialized work. The cable must be as compact as possible, but at the same time, components must be able to remain intact while applying load to the cable and while bending and flexing the cable. How should my opto-electrical cable core be constructed to survive the high loads applied while remaining flexible?

Lists by Topic

- ROV Cables (18)

- Seismic (14)

- Naval Defense (12)

- Naval cables (12)

- Cable solutions (10)

- Cable design (9)

- Subsea cables (9)

- Deep-sea cables (7)

- Renewable Energy (7)

- Field Service (6)

- Fields Service (6)

- Innovation (6)

- News (5)

- ROV (5)

- Cable requirements (4)

- Renewables (4)

- Seismic source umbilical terminations (4)

- cables (4)

- Cable specification (3)

- Design considerations (3)

- ROV innovations (3)

- Subsea (3)

- Umbilical products (3)

- Bespoke marine cables (2)

- Deep sea mining (2)

- Defense (2)

- Oil & Gas (2)

- Seabed equipment terminations (2)

- Umbilical cables (2)

- design (2)

- manufacturing (2)

- Aramid (1)

- Dynamic cable design (1)

- Flexible terminations (1)

- HSE day (1)

- Heidrun platform (1)

- Lightweight balloon tether terminations (1)

- Maintenance (1)

- Raw materials (1)

- Seismic lead-in terminations (1)

- Spare parts (1)

- Steel (1)

- Termination specification (1)

- Testing (1)

- Thermal analysis tool (1)

- company video (1)

- development (1)

- experience (1)

- facilities (1)

- fibre (1)

- requirements (1)

- research (1)

- service (1)

- supplier (1)

- test (1)

- video (1)

.jpg)