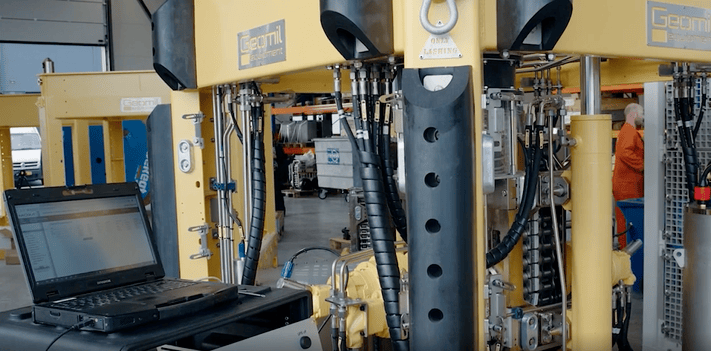

Subsea projects sometimes take place in the most harsh conditions of the world. A company that is known for its solutions within these harsh environments is Geomil Equipment. They design and manufacture equipment for cone penetration testing methods - a technique to test the bearing capacity of soil, onshore as well as offshore.

In fact, Geomil Equipment works together with DeRegt for offshore cone penetration testing. We interviewed Ed Smit, Head of Sales at Geomil Equipment, about the collaboration with DeRegt and the challenges this team-up solves.

Providing solutions in the most harsh environments

”Geomil Equipment has developed into a worldwide exporting company. Nowadays, we are the market leader in the field of cone penetration testing methods,” Ed Smit explains. “However, this means many companies rely on us to provide solutions for the most harsh conditions. This is quite challenging at times. There were three main challenges we encountered.”

“One of the biggest challenges in these environments is downtime. Working offshore on vessels with 24/7 operations means that all our equipment has to be designed to reduce downtime. All of the components must be of the highest quality to ensure a long lifetime.”

“This 24/7 approach also requires continuous service, which is something not all partners can deliver,” Ed Smit continues. “The third challenge is that more and more projects require working at great depths, which demands the right equipment.”

An evolving partnership

”The partnership with DeRegt started with a shallow water solution of approximately 150 meters,” Ed Smit looks back. “It has evolved to a 4000-meters solution without any loss of capacity.”

“The cables we developed together with DeRegt have a smaller diameter than the previous cables, and they can generate the same capacity at great depths. This not only solves the equipment challenge of working at deeper waters, but with DeRegt we are able to respond 24/7 if necessary.”

“Last but not least, DeRegt applies the same policy when it comes to components. Both companies want to make downtime as limited as possible to make sure the subsea projects of our customers are successful.”

Read more about minimizing downtime in this blog.

Solving challenges together

“With the partnership between Geomil and DeRegt, we could solve our three main challenges together,” Ed Smit proudly concludes. “It is a textbook example of how a partnership between two companies should be.”

“For example, it enables us to operate worldwide 24/7. When we call DeRegt, they are always on standby, and they always give a solution to our senior engineers. Thanks to this, we are able to serve our customers the very best service.”

“Additionally, the partnership provides us with more possibilities thanks to the subsea cables that allow us to work on greater depths with the same capacity. This opens many doors for new types of projects.”

Subsea projects and the added value of trustworthy partners

There are numerous examples of subsea projects that benefit from fine cooperation, such as between Geomil and DeRegt. Such collaborations create something we call co-creation, working together to create a product that solves the challenges of all parties.

For the ROV market, we created a webinar on the phenomenon of co-creation and its benefits this might have for your project. Watch this webinar here:

Companies in the Seismic market also benefit from long-term partnerships. Read more about what this means for your project in our Case Study with PGS.