For 40 years or more, ROVs have been used for underwater tasks in oil & gas drilling, defense and ocean research. Over time, ROV technology has vastly improved in size and sophistication. While seemingly mundane, the cables that transmit power, communications, and data to and from the ROV have also become quite sophisticated.

Since those early beginnings, a new emphasis on renewable energy resources has accelerated the use of ROVs for installing offshore wind turbines, and more recently wave and tidal (ocean) power. As coastal waters become more crowded, power companies are branching into deeper waters.

Towards Sustainability: From Hydraulics to Electric Motors

The social and regulatory costs of energy are increasing, as countries around the world sign on to agreements such as the 2050 NetZero pledges. With this global trend towards increasing sustainability and clean technology, OEMs are beginning to develop partial- or full-electric work-class ROVs, or eWROVs. And advanced subsea cables designed with new materials are essential to the success of these next-generation machines.

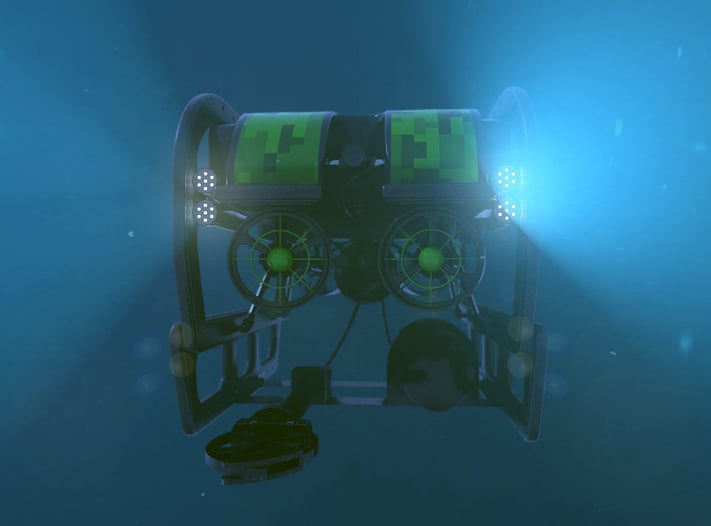

Several OEMs have made strides in building all-electric ROVs for lighter jobs at relatively shallow depths. Some are now producing large eWROVs with more power and deeper ratings.

Conventional ROVs use hydraulics to drive thrusters and ancillary equipment. The electric motors driving the hydraulic packs run almost continuously. Driving electrical thrusters and equipment directly reduces the power consumption when idling and eliminates the heavy hydraulic power packs, though a larger transformer to reduce the transmission voltage to useable levels offsets some of the gains The net result is a higher power machine running on the same, or smaller, cable for the same spec ROV.

This efficiency gain could prove to have a beneficial compounding effect. If all-electric ROVs require less power to operate, they only need a smaller diameter conductor. This, in turn, could fit into a smaller, lighter umbilical cable, which corresponds to a smaller winch aboard ship, which uses less deck space on the rig boat or vessel – reducing costs at each step along the way.

Deepwater cable technology complexities.

Compared with earlier ROV designs, deepwater and “work-class” ROVs require more power, and more electrons coursing through increasingly long umbilical cables. More strength is needed to lift the same ROV with a longer cable. Otherwise, the cable breaks or simply won’t reach the target depth.

When a vehicle dives below 3,000 or 4,000 meters deep, the protective steel armoring becomes too heavy for such long cables. At the same time as the cable must become more reliable and lighter in weight, it needs to withstand increasing hydrostatic pressure without being crushed.

Using lightweight materials such as synthetic fibers for a strength member is one solution. However, these synthetics increase the size of the cable and have less crush-resistance than steel. Also, synthetics do not conduct heat, making cable design more complicated. To overcome challenges with lightweight synthetics, DeRegt is constantly testing different materials and innovating with new cable designs to help companies in several industries to expand their businesses.

The Role of Cables in ROV Performance and Efficiency

Designers of subsea cables for all-electric work-class ROVs face the challenges of reducing weight, increasing reliability, and reducing maintenance and downtime.

No two ROV cables are alike. The final design, including diameter and length, configuration of conductors, and strength member materials used, will depend on the type of motors (electric vs. hydraulic), the tasks to be completed, and the depth and location. The move to electrical propulsion and deeper waters will require different cable structures that can withstand one of the harshest environments on Earth.

Deeper waters are not accessible to divers, so ROV reliability is key, and it goes without saying that reliability affects cable design.

Equip Yourself with the Right Knowledge

If your company is looking to design new electric components to replace hydraulics for ROVs, extensive testing is required. At DeRegt, we have experience prototyping and testing new subsea cable materials and designs. We would be happy to talk with you about how cables can complement and enable your ideas.

Engaging on this co-development level with you as your ideas progress can improve the outcome for your eROV project. To learn more about subsea cable design, download the ebook 'ROV Cables: The Ultimate Guide' to increase your understanding of ROV operations.