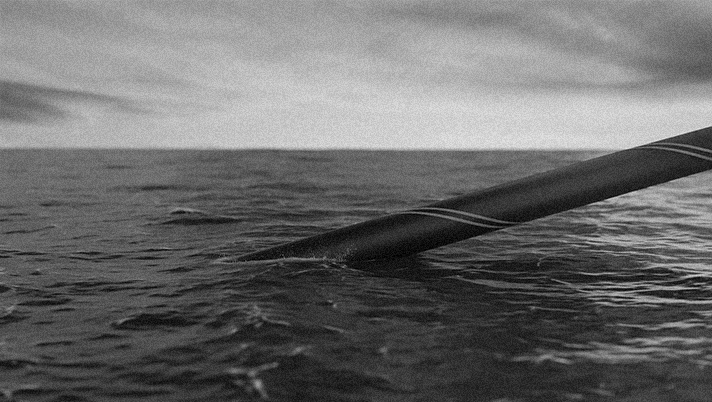

Proper cable handling is essential for ensuring the longevity and reliability of your cables. Whether you are shipping, moving, unpacking, or storing them, any mishandling can result in damage that can be time-consuming and costly to fix or replace.

The Importance of Correct Handling to Prevent Subsea Cable Damage

Apr 26, 2023 9:30:25 AM / by Mario Boot posted in Remotely Operated Vehicles, Energy, Defense & Security

Improving Sonar Cable Performance With Ultra

Aug 30, 2022 11:45:00 AM / by Jeroen Romijn posted in Defense & Security

The Navy monitors safety at sea worldwide. That’s a tough job in challenging circumstances. Many countries have navy vessels with sonar systems that are equipped with DeRegt Cables. These are developed in cooperation with Ultra, a leader in underwater warfare technologies.

Steel vs. Aramid fibre - what is the best cable solution for your subsea project?

Aug 23, 2022 3:00:00 PM / by Phil Roscoe posted in Remotely Operated Vehicles, Energy, Defense & Security

Engineers within subsea projects are often unsure of the pros and cons of steel armoured cable or aramid fibre armoured cable. How can you know the most beneficial armouring for your subsea project as an engineer?

Three advantages of Early Supplier Involvement

Aug 16, 2022 9:30:00 AM / by Jeroen Romijn posted in Remotely Operated Vehicles, Energy, Defense & Security

Why is it important to involve your cable supplier early in developing your new product or equipment? At DeRegt, we often see customers who have succeeded in developing an excellent Sonar or ROV system but forget to think of the cables involved or underestimate their complexity.

How To Validate Subsea Cable Designs

Jul 14, 2022 1:50:49 PM / by Sander van Leeuwen posted in Defense & Security

When you engineer subsea cable systems for naval or offshore missions, every requirement needs to be proven — not assumed. Depth, pressure, loading, electrical behavior, safety factors… none of it matters unless you can verify that your cable meets the specifications for which it was designed. That’s where structured verification becomes essential.

A clear Design Compliance Matrix (DCM) provides full traceability from the initial requirement to the final test. It shows how every spec will be inspected, measured, demonstrated, analysed, or tested. And provides the evidence needed to prove compliance before the cable goes to sea. The DCM is the foundation for reducing risk, avoiding redesign costs, and ensuring your cable performs reliably in harsh marine environments.

In this article, we explain how the Design Compliance Matrix works, why it matters, and how it helps you verify every requirement in a structured, engineering-driven way (including examples).

6 Environmental Sonar System Requirements and how to verify them

Jul 7, 2022 5:06:42 PM / by Sander van Leeuwen posted in Defense & Security

In a previous blog, we listed all types of sonar system requirements. A couple of verification methods can be used to verify your cable specifications. Extensive testing can’t always be avoided, but luckily, some offshore cable specifications can also be verified by analysis. After all, a lot of data is available on materials and surroundings.

Environmental sonar system requirements are essential requirements in the naval world. Fortunately, these requirements are examples of analyzable specifications. They usually do not require expensive testing, since materials and the environmental conditions they can handle are documented. In this blog, we will list the most common environmental requirements and how we make sure they are verified by analysis. There’s also one exception to this rule.

Engineering Better Outcomes Through Early Supplier Involvement

Jul 7, 2022 5:06:03 PM / by Nicole van Leeuwen-Becht posted in Defense & Security

Successful naval systems depend on components that work together from day one — and subsea cables are no exception. Their mechanical loads, routing, interfaces, and fatigue behavior all influence the overall design more than most teams realize at the start. That’s why involving your subsea cable partner early isn’t just helpful; it’s a strategic engineering advantage.

Early Supplier Involvement (ESI) gives your project the clarity, feasibility insights, and technical foresight needed to avoid late-stage redesigns. It aligns system architecture with cable realities, reduces risk, and accelerates your path to a reliable, mission-ready solution.

Below, we outline the most important outcomes ESI brings to naval cable projects.

Essential Qualification Tests for Subsea Defense Cables

Jul 7, 2022 5:04:23 PM / by Manuella Hoogendijk posted in Defense & Security

In underwater defense systems, a cable is only as reliable as the qualification behind it. Depth, pressure, tension, bending cycles, temperature swings — every mission profile exposes a subsea cable to extreme forces. That’s why rigorous qualification isn’t a formality. It’s the foundation of operational certainty.

For naval engineers, the real challenge is balancing feasibility, performance, safety margins, and lifecycle cost. Testing plays a key role, but it isn’t always the most efficient starting point. In many cases, analysis or simulation provides the insight needed to advance the design, reserving full-scale testing for the moments when it truly adds value.

Below, we outline the essential qualification tests typically used to validate whether a subsea defense cable is ready for deployment.

Subsea Cable Design: The importance of a clear Design Process and timely freezing your design

Jun 21, 2022 1:40:57 PM / by Sander van Leeuwen posted in Defense & Security

In creating a Subsea Cable Design, there are a lot of aspects to consider. It is important that the final design properly fits into your sonar system (or the subsea system you’re creating). As an engineer, you want to have a firm grip on the project. The decisive ingredient in doing that is a clear design process.

In this blog, we discuss the advantages of having such a design process in place, the design process of our cable experts and how this subsea cable design process will eventually help you in properly validating your specifications.

The Five Sonar System Requirements That Define Your Cable Design

Jun 21, 2022 1:40:37 PM / by Nicole van Leeuwen-Becht posted in Defense & Security

Every reliable sonar cable begins long before materials are selected or drawings are made. It starts with the system requirements: the mechanical, operational, environmental, functional, and regulatory factors that determine how the cable must behave in real naval conditions. Get these requirements right, and you build a cable that performs predictably under extreme loads and harsh environments. Get them wrong, and the risk of redesign, failure, or reduced mission capability grows quickly.

For naval engineers, these requirements are not just documentation — they are the foundation of the entire design process. They define how the cable must move, survive, and transmit data and power throughout its lifetime.

Below, we outline the five key sonar system requirements that shape every subsea cable design.