When your system moves with the ocean, your cable needs to move with it.

Dynamic umbilicals are becoming essential in wave energy, floating wind, and next-generation offshore renewable systems. They’re the lifelines that transfer power and data while surviving constant mechanical stress: bending, torsion, tension, and fatigue.

But how do you design an umbilical that truly matches your system, environment, and loading conditions? In this guide, we walk through the core building blocks of a dynamic umbilical and explain where engineering choices make the biggest impact.

For over 50 years, DeRegt has engineered subsea cable systems designed for environments where failure is not an option. We bring that experience to your team as you take bold new energy concepts offshore.

The anatomy of a dynamic umbilical

Every layer has a job. Every choice has a consequence.

At the heart of the cable, everything revolves around two critical functions: power delivery and data integrity. The advanced technology sits inside, but the outer layers determine whether that technology survives real offshore conditions.

Below are the components that define how a dynamic umbilical performs in the field.

Power Transmission

Your system needs reliable, predictable power — regardless of ocean movement.

Copper is the standard conductor in power export cables. The amount of copper is driven by power level and voltage requirements.

- Up to 5 kV: single-layer power cores

- Above 5 kV: triple-layer extruded power cores with individual shielding → suitable up to ~33 kV and engineered for higher safety and stress distribution demands.

These choices influence not just electrical performance, but how the cable behaves under dynamic loads.

Overview of a dynamic power cable

Data Transmission and Fiber Optics

Power means nothing without control.

Wave and tidal systems generate massive amounts of data — motion, loading, temperature, system performance. That information must move fast, clean, and reliably to the surface or shore.

Copper works for small data volumes, but modern systems rely on fiber optic transmission:

- high bandwidth

- low attenuation

- engineered to handle mechanical stress when properly protected

- compatibility with fiber optic sensing, turning the cable itself into a monitoring device

Sensing will become essential for offshore health monitoring and predictive maintenance.

Sheaths and Tapes

Protecting the core from the ocean, and the ocean from the core.

The core is sealed inside a polyethylene sheath. Water-blocking tapes can be added when additional barriers are required. Semiconductive layers help create a radial field and distribute electrical stress evenly. Metallic tapes or earth screens provide ground reference and safe fault-current paths.

Because every offshore system is different, this part of the design is always customized.

Armoring

Where strength meets flexibility. Armoring gives the umbilical its strength, stiffness, and mechanical protection.For dynamic systems, two-layer, torque-balanced armor is key:

- uniform resistance in all directions

- controlled torsion and fatigue

- added protection against impact, abrasion… and yes, even sharks

An extruded outer sheath protects the assembly from seawater and wear throughout its life. Dynamic cable with shark bites

Dynamic cable with shark bites

Additional system components

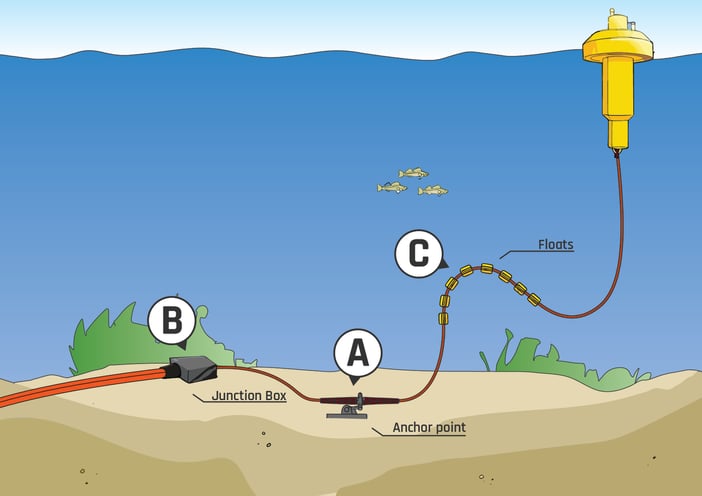

A cable never works alone. It’s one part of a moving, loaded, integrated offshore system. Overview of a wave energy conversion system with its cables and other critical components

Overview of a wave energy conversion system with its cables and other critical components

a. Landing points & load transfer

Your device’s motion creates tension in the cable.

Load transfer components safely redirect these forces into reinforced structural points — both topside and subsea.

b. Terminals & plugs

Depending on your environment and testing needs, we use oil-filled junction boxes, dry-mate, or wet-mate connectors.

c. Configurations for controlled motion

The transition from static to dynamic is always a high-risk zone.

That’s why bend stiffeners, lazy-S, or J-lay configurations are used to distribute tension and minimize fatigue.

Unique opportunities and challenges

Prototyping at sea leaves no room for guesswork. The earlier you map out design options, risks, and integration points, the faster you move toward a reliable prototype. A custom umbilical typically takes about six months to develop — and every week you start earlier reduces downstream risk.

Want to explore your system’s options? Schedule a Feasibility Check with our engineers. We’re ready to co-create the best technical and commercial choices for your concept.

Every challenge is unique. Let’s discover what your system needs to perform offshore.

Every renewable energy system and related challenges are different, so we’d love to hear about your unique opportunities and challenges!